Savar intelligence helps lithium battery industry enter a new era of intelligent manufacturing

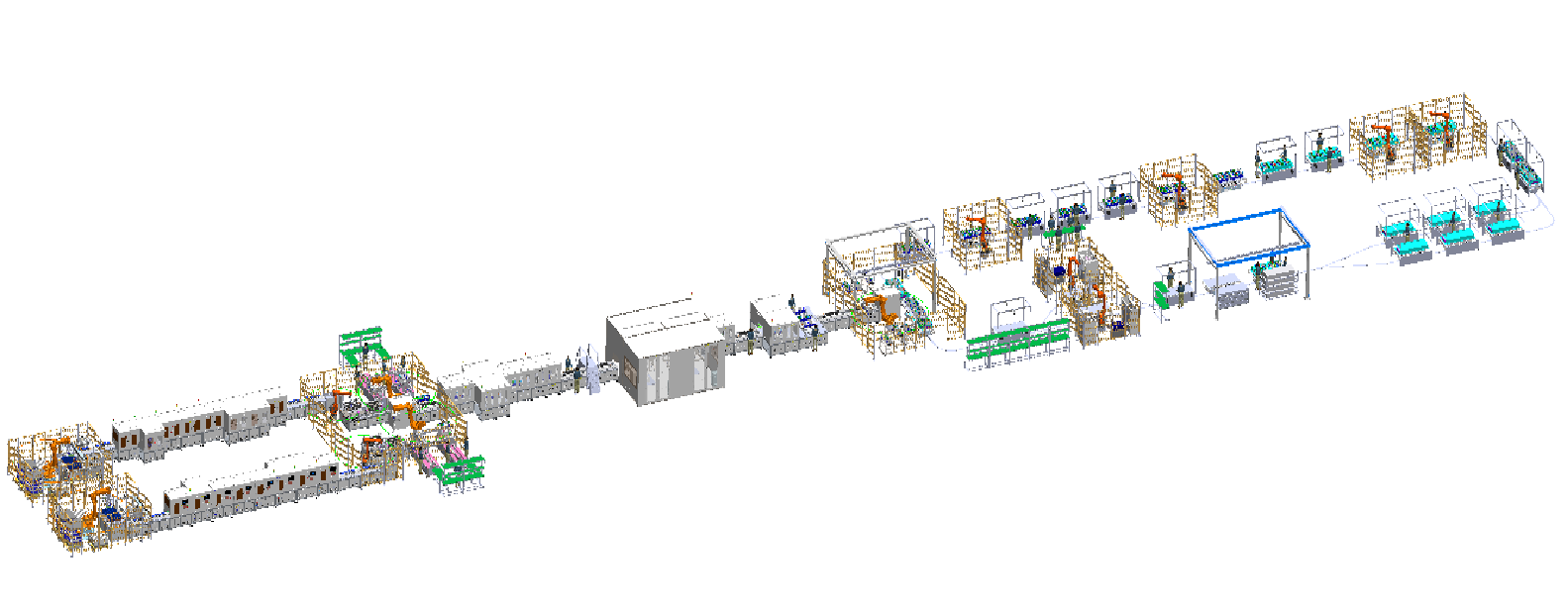

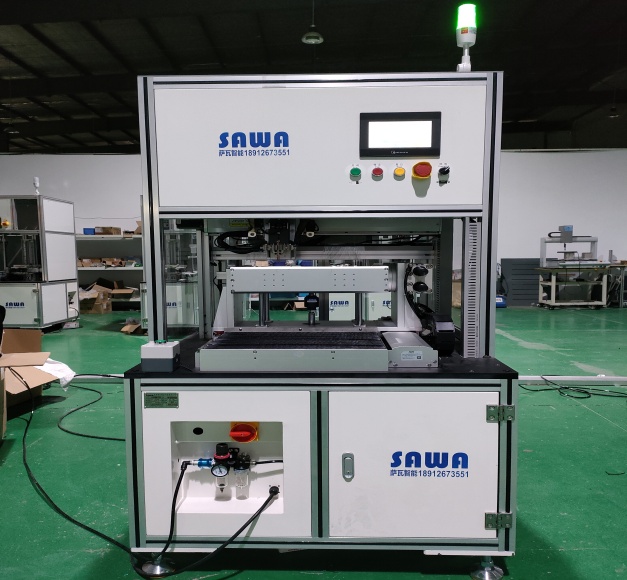

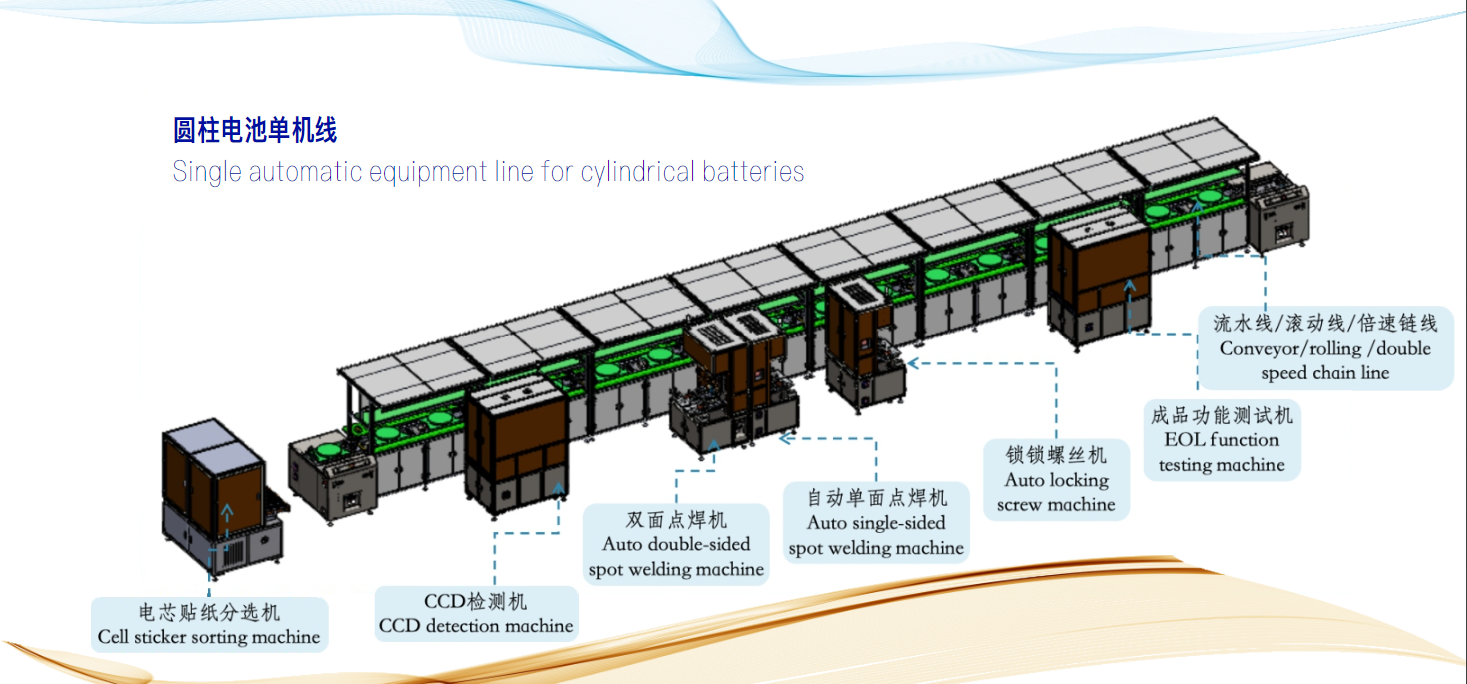

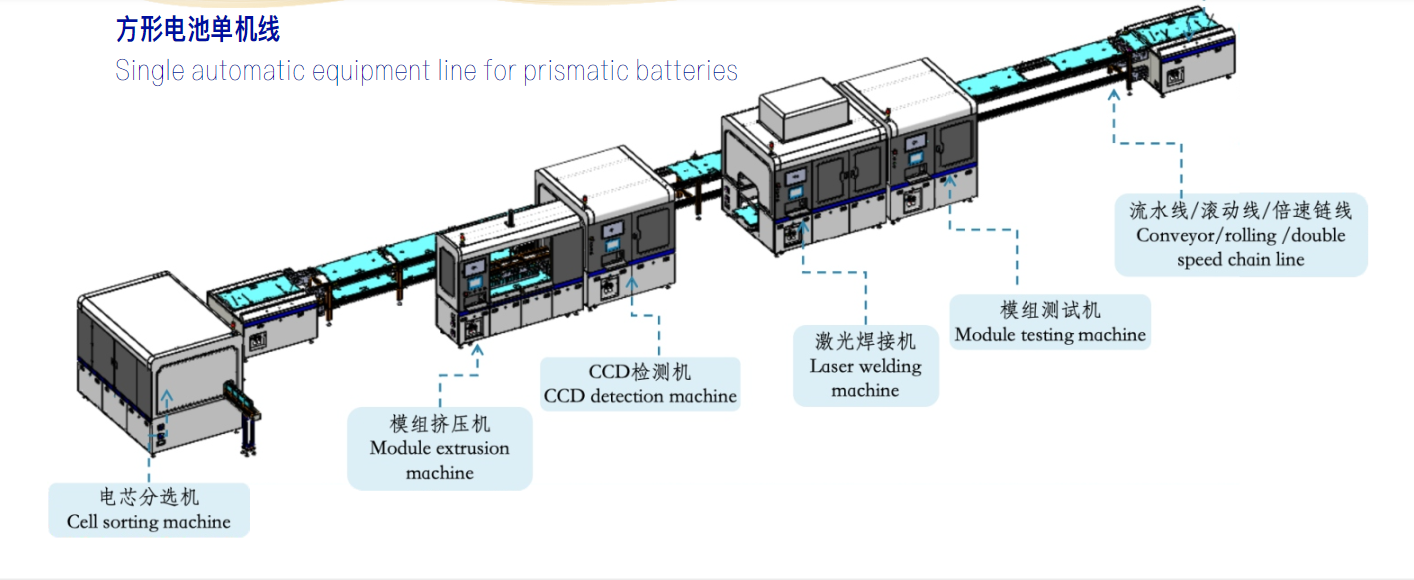

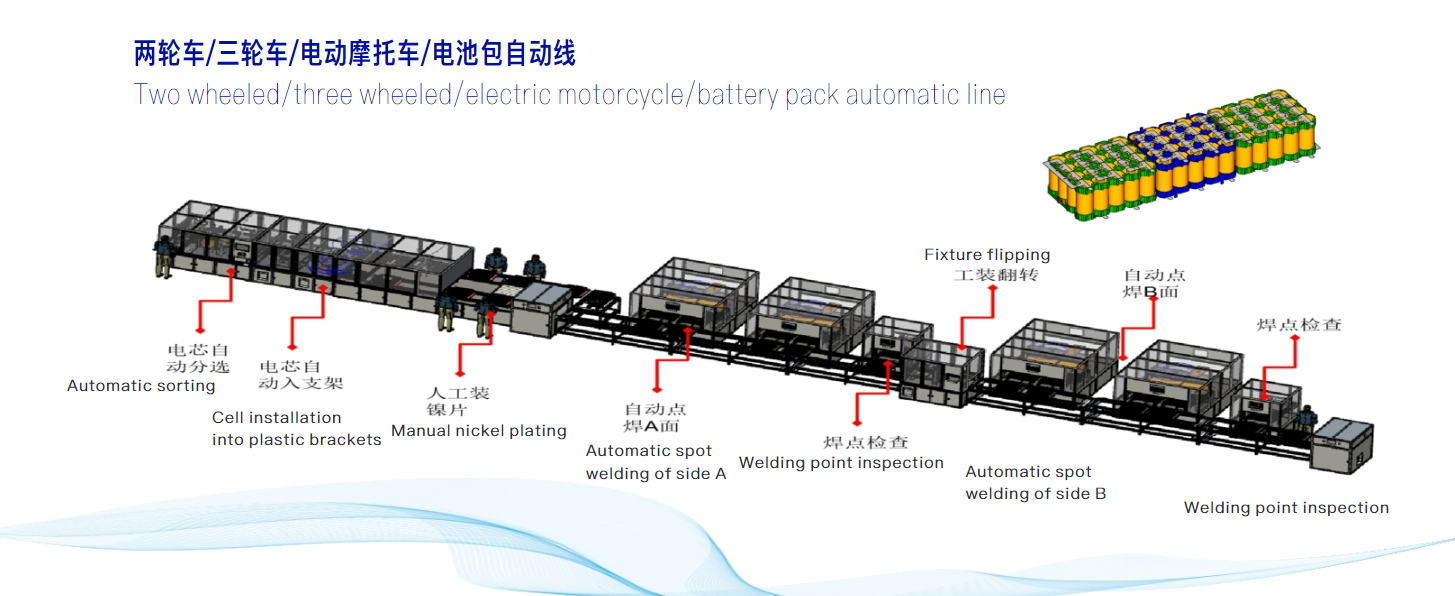

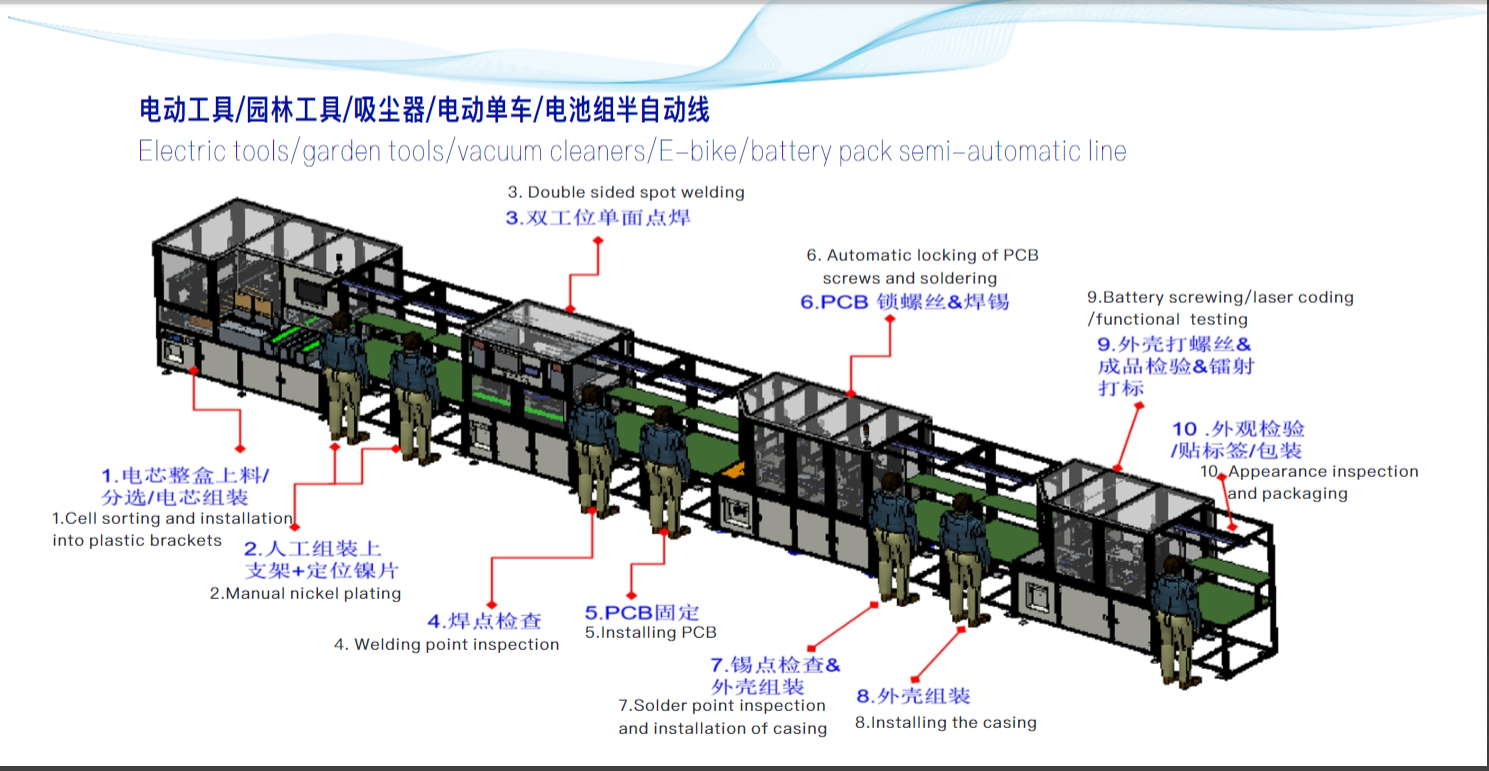

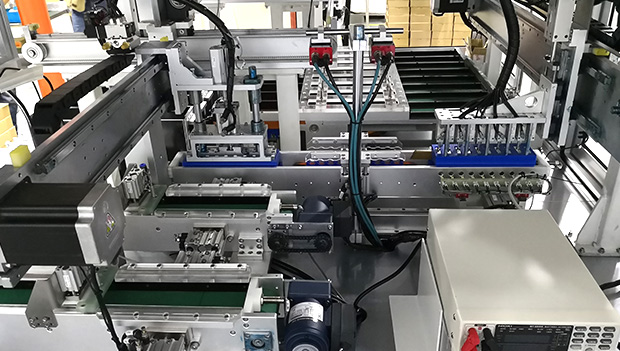

Savar intelligent focuses on the customized production service of lithium battery automatic production equipment and automatic production line. Savar intelligent can tailor-made solutions for customers, improve the production efficiency of customers, and realize the comprehensive replacement and upgrading of automatic production equipment in lithium battery industry.

>17Years of industry experience >8000㎡production base >17Patent certificates >1Monthly customized delivery